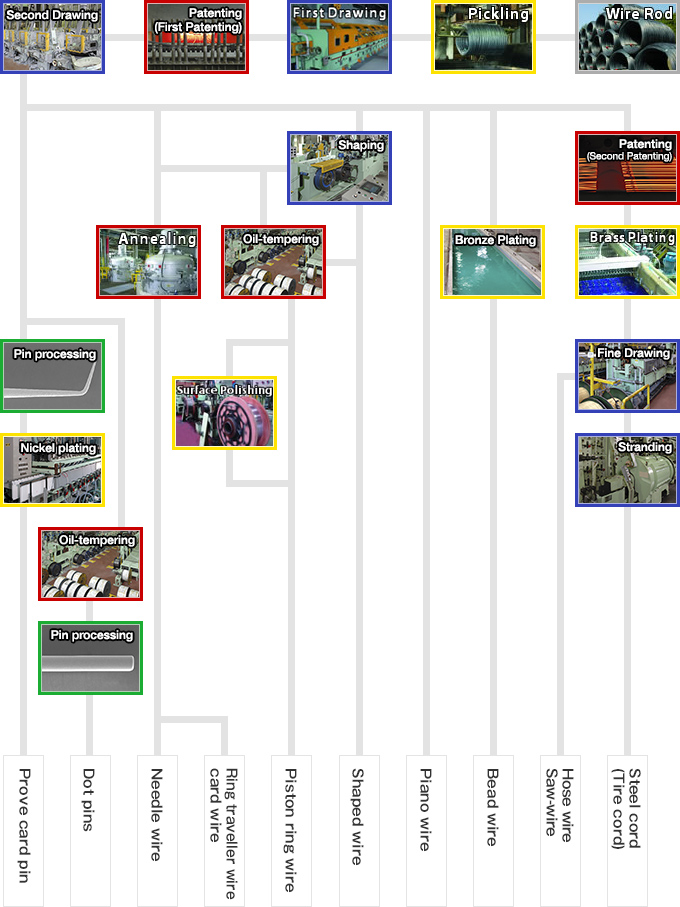

Technology Development -Manufacturing process-

- Head Office Plant

- On a huge site of 400,000㎡– 10 times the size of a professional baseball stadium – this plant produces products requiring sub-micron level processing. The surrounding natural environment is a scenic delight of colorfully changing seasonal beauty.

Cold working technologies

| Wire drawing | 5.5-mm thick metal wire material is drawn into thin, tough wire. |

|---|---|

| Shaping | A diverse range of cross-sectional shapes is achieved by special rolling and drawing techniques. |

| Stranding | Various types of stranding machines make possible a wide variety of stranding configurations. |

Heat treatment technologies

| Patenting | Restores the toughness of intermediate wire and produces a structure with excellent drawability and rollability. |

|---|---|

| Annealing | Produces a spheroidized structure and restores the processability of standard carbon steel, low alloy steel, and stainless steel. |

| Oil-tempering | Various types of furnace are used to increase the straightness and strength of materials, ranging from standard carbon steel to stainless steel. |

Surface treating technology

Various types of plating, including brass, bronze, zinc, nickel and composites, are used to obtain the special characteristics required for each application.

Micro precision processing technology

Micro processing technologies include round processing, step processing, and taper processing of the end faces of extra fine wire.