Technology Development -Manufacturing Plant-

INNOVATION Perfecting the "essence" of precision processing and applying it to new fields

Semiconductors, solar power generating equipment, office equipment, communications equipment...Special steel wire made possible by Tokusen’s unique technologies is indispensable to many products for which Japan is famous.

Thinner,precision,and more tough,with a uniformly consistent shape.

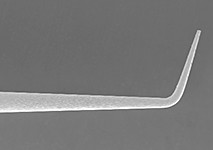

Tokusen’s world-leading technology achieves a remarkable precision of +/-0.2 micron, enabling ultrahigh precision taper processing of pins for precision equipment. As industries continue to demand ever higher precision, Tokusen’s technology has risen to the challenge.

Our widely recognized technological prowess is also contributing to the medical industry, where technology is advancing at an impressive pace.

Processing technologies

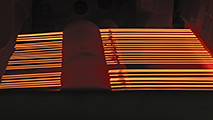

Wire Drawing

Drawing is the basic technology used for wire production.

With our unique technology, we are able to draw 5.5 mm thick metal wire material down to the required diameter without having to perform intermediate heat treatment, and draw down to a final diameter as thin as 0.01 mm.

Shaping

Tokusen’s highly praised shaping technology is unrivaled.

Proprietary know-how enables us to draw metal wire into complex cross-sectional shapes by die drawing and rolling, and also by combining these two processes to create any desired shape.

Stranding

Heat Treatment and Surface Treatment

Special Processing (Micro Precision Processing)

The world’s highest processing precision.

Micron-level dimensional precision.

Such precision is achieved by combining state-of-the-art processing equipment, including some of original design, with a constant effort to stay one step ahead of customer needs.