Technology Development -Technologies for new Product Development-

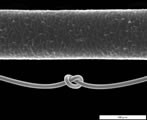

Finer, tougher, more varied products

By building on basic technologies accumulated over 40 years, Tokusen is combining a wide array of techniques and materials to create highly functional wires meeting demand for high strength, super ultrafineness, and high precision.

High-performance surface treatment/surface modification technologies

Tokusen develops products that help improve corrosion and wear resistance, and provide various added functions.

- 1.Adhesion performance

- Steel cord used for tire reinforcement is brass-plated to help it stick to the tire rubber.

- 2.Cutting performance

- Attached abrasive grain saw wire used to cut highly brittle materials is made using electrodeposition technology to enable the diamond grains to stick to the wire.

- 3.Electrical characteristics

- Electrode wire used to discharge ultrafine wires in microminiature processing is surface-treated for high discharge performance.

Tokusen will continue creating similar high-performance, multifunctional surface treatment technologies to develop products for fields such as energy, the environment, and medicine.

Plating Technology

- Straightening Technology

- Processing methods tailored to each wire type ensure outstanding straightness.

- Centerless Technology

- Creates tapered or perfectly circular shapes with outstanding dimensional precision using a proprietary processing unit.

- Cutting Technology

- A continuous wire cutting process that enables shapes impossible with rolling technology alone.

Tokusen's various wire types can be plated with a brass, bronze, nickel or copper surface treatment to provide the required characteristics.

Just 0.005 mm thick. Supports widths unachievable with slit processing.

Just 0.005 mm thick. Supports widths unachievable with slit processing.  Just 0.10 × 0.10 mm in size. Has a greater cross-section surface area than round wire, enabling finer wire of the same strength.

Just 0.10 × 0.10 mm in size. Has a greater cross-section surface area than round wire, enabling finer wire of the same strength.